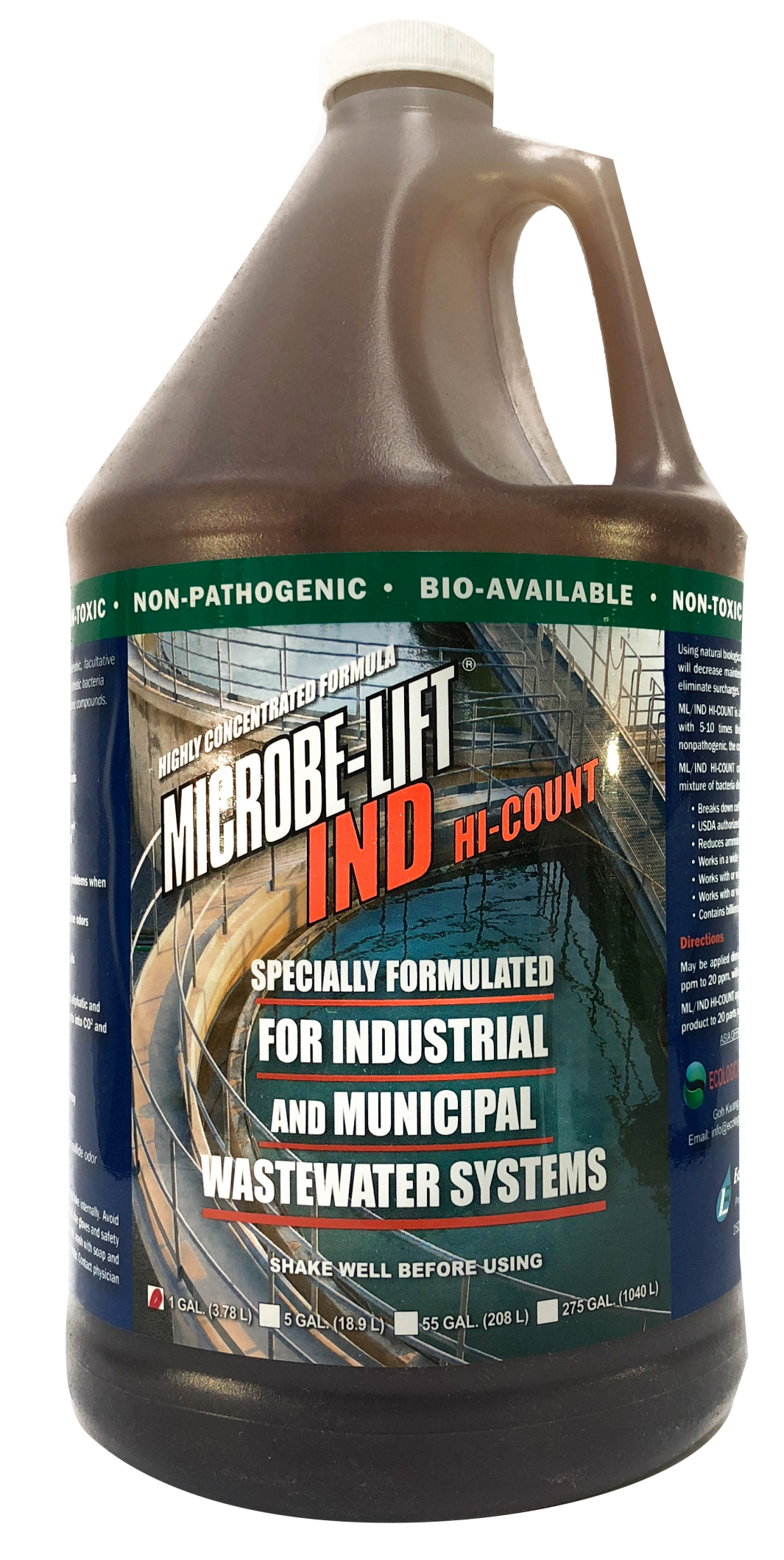

MICROBE-LIFT IND

MICROBE-LIFT IND is a highly active liquid culture consortium design specifically for use in all industrial and municipal wastewater systems. MICROBE-LIFT IND contains a blend of 29 select microorganisms with a specification of 10^9 cfu / ml. MICROBE-LIFT IND cultures accelerate the biological oxidation of slow to degrade organic matter in aerobic, facultative anaerobic and anaerobic wastewater systems, ponds, lagoons and wastewater retention tanks. MICROBE-LIFT IND enhances the biological oxidation of slow to degrade organic compounds significantly improving overall system performance and stability.

MICROBE-LIFT IND select cultures promote increased biological degradation capabilities in all types and designs of biological wastewater systems. They increase the degradation rate of slow to degrade, difficult to degrade and many non-biodegradable compounds that have shown to negatively impact wastewater system performance. They resist high concentrations of inhibitory constituents; improve system performance, reduce system upsets and biomass kills common to industrial and municipal wastewater systems.

MICROBE-LIFT IND increases overall microbial oxidation rates, significantly increasing organic degradation performance. This novel microbial consortium provides reductions in final effluent BOD, COD, SS, and improves settling in final clarifiers, while reducing waste sludge volume in difficult to degrade compounds such as, fatty acids, various chemical compounds, hydrocarbons and fibrous matter.

Microbe-Lift IND products are an excellent bioremediation based bacteria that works well in the following applications:

- Achieving ecological balance of natural bodies of water such as polluted lakes and lagoons; along with reducing flying insect population;

- Economical treatment of agricultural waste using simple oxidation ponds such as used in swine and duck farms where large amounts of waste water are produced daily, eliminating odor, while enhancing fertilizer value of treated effluent;

- Enhancing the effectiveness of municipal and industrial wastewater treatment plants and increasing the operation efficiency and capacity;

- Improves water quality in fresh water shrimp and fish farms, reducing mortality rate and increasing yield and quality, while reducing feed;

- Restaurant and Hotel grease trap treatment- reducing fats-oils-grease for easier removal, as well as controlling bad odors;

- Reduces the need for regular sludge removal in septic tanks, eliminates odor, and in many cases can rejuvenate failed septic systems;

- Reduce pest such as cockroaches, rats, mosquitoes drastically in the septic tanks and drain lines;

- Improve biogas generation in anaerobic digester;

- Hydrogen Sulfate removal, particularly in petroleum storage tanks, thereby preventing tank corrosion.