DRAIN LINE AND GREASE TRAPS

Grease Traps are basically holding tanks with baffles which allow oil & grease in a usually warm or hot liquid waste stream to cool off and float to the surface of the trap where the baffle keeps it from exiting the system. In this way, the grease trap reduces the organic loading to the wastewater treatment system. Moreover, bodies of water with oil & grease build up on the surface become an anaerobic environment that prevents sunlight and air to pass through the surface of the bodies of water.

These are common problems in industries, commercial establishment, and residential condominiums with high load of kitchen wastes that produce oil & grease wastewater.

Indigenous bacteria degrade oil & grease that accumulate in the grease trap while new oil & grease are being built up. The speed of new oil & grease build up often exceed the natural biological degradation. The excess floating oil & grease requires regular pumping for disposal.

Oil & grease are the main causes of clogged pipes, and low efficiency of pumps when excess oil and grease wash out in grease traps. Consistent hauling is the only one solution for maintenance of grease traps but it is costly especially it should be done once a month.

COMMON ISSUES

Organic solid reduction

Solids are plentiful in any septic system and needs to be digested to its basic elements of Carbons, nitrogen, phosphorous and sulphides. Our bacteria will effectively digest these solids to its base elements leaving you with a free flowing system that does not clog up.

High Fats, Oils and Grease

Fats, oils and grease can clog up pipes and build up in your septic system reducing your flow rates and lowering the amount of waste a system can take.

Our bacteria effectively digests these Fats, oils and grease to their base elements of water and carbon dioxide gas. This insures a free flowing system with no blockages and far less call outs from the septic tank pumpers.

Horrible odours

Odours in a septic system is caused by the generation of Hydrogen sulphide gas. This is a natural process and a result of solid digestion. However this is not a pleasant smell at all and greatly affects all people in the area.

Our product contains bacterial strains that specializes in the breakdown of Hydrogen sulphide. We very effectively get rid of all odours associated with aseptic system.

Imagine a septic system that if continually free flowing, free of odours and requires very little to no maintenance. We can make it happen.

OUR SOLUTION

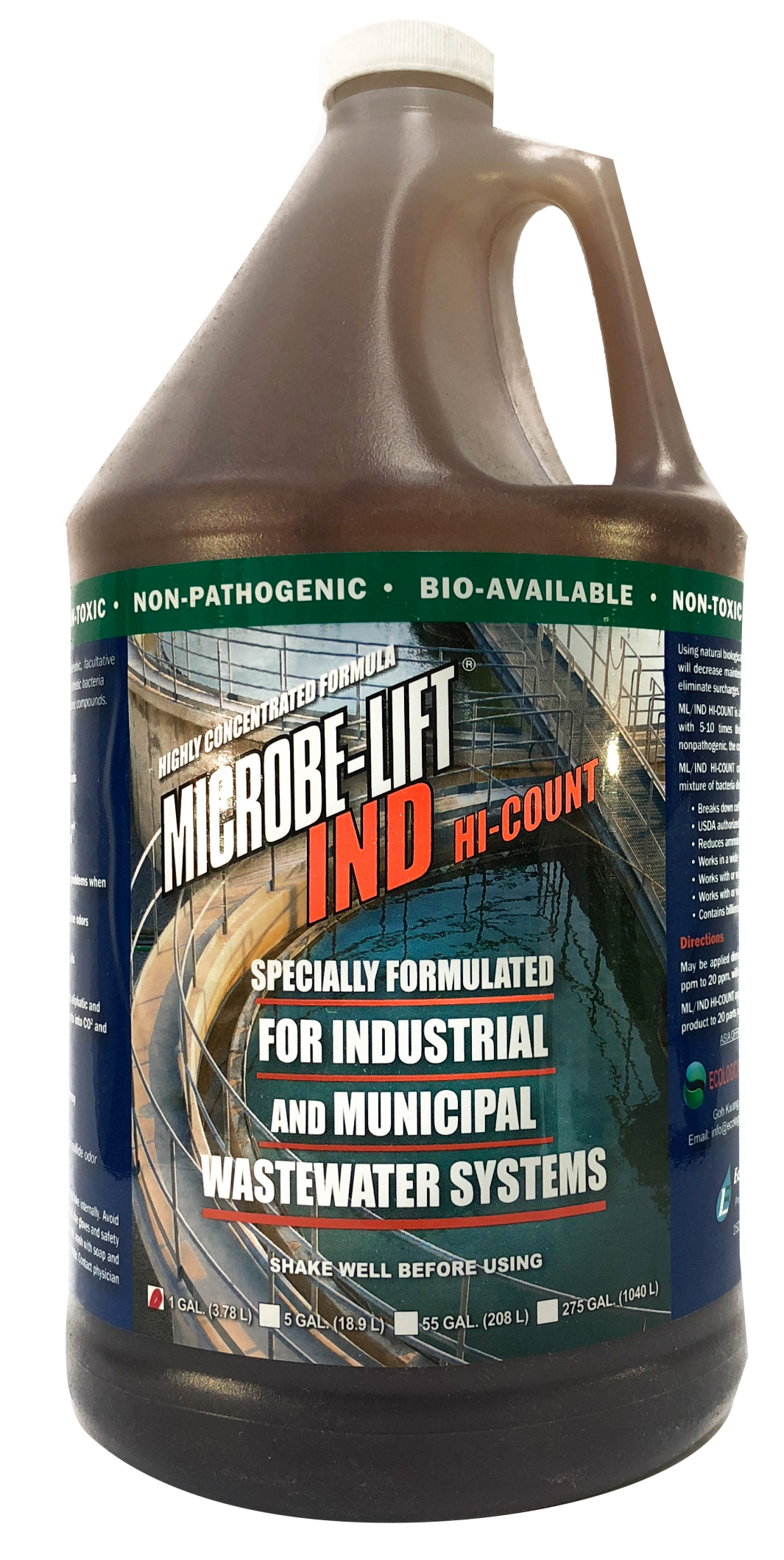

Microbe-Lift® Technology provide liquid microbial solutions for environmental applications and improve the performance of the environmental treatment facilities naturally using the most advanced biotechnology available in the market today. The bacterial solutions that we provide are natural and the only product available in the market to contain the most diverse consortium of beneficial microorganisms, a perfect fit for DENR +63 918 884 6825 (Water Quality Guidelines and General Effluent Standards) compliance.

Microbe-Lift remediation of grease trap helps to speed up the oil & grease degradation and eliminate bad odours particularly during pumping of excess oil & grease. Microbe-Lift DGTT is recommended for grease trap treatment.

Grease traps are generally designed with a minimum of one (1) hour hydraulic retention time during the peak flow. Dosing rate is based on grease trap size, however, should peak flow rate per hour higher than the grease trap, dosing should be based on the peak flow rate volume.

Microbe-Lift DGTT liquefies oil & grease build up and converts it into water and carbon dioxide (CO2). It is best to combine Microbe-Lift IND with Microbe-Lift DGTT to increase the performance of oil & grease degradation.

Weekly dosing of Microbe-Lift DGTT and Microbe-Lift IND diluted in water is required.